|

UNITED STATES AIR FORCE |

|

COMMEMORATIVE BRONZES |

|

A PUBLIC AND PRIVATE MISSION THAT HONORS OUR USAF HEROS AND FELLOW BROTHERS IN ARMS |

|

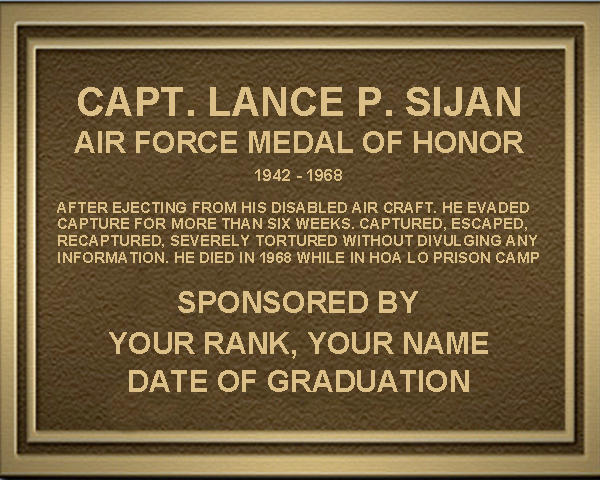

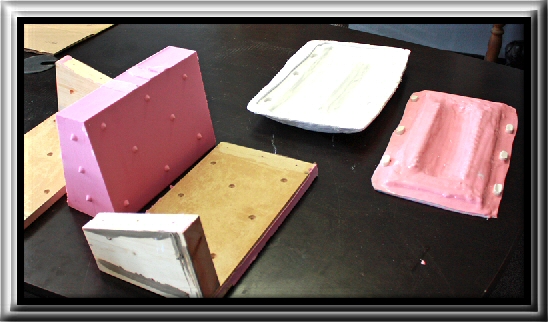

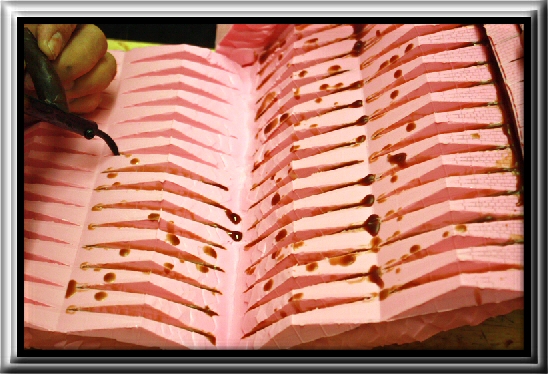

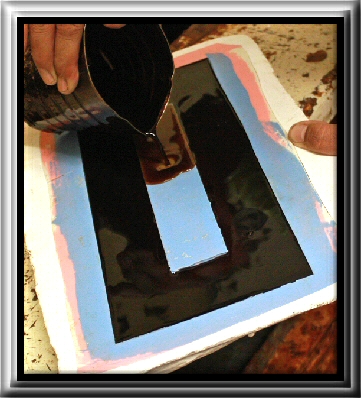

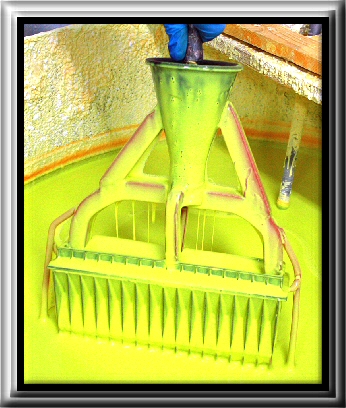

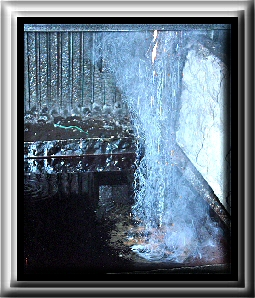

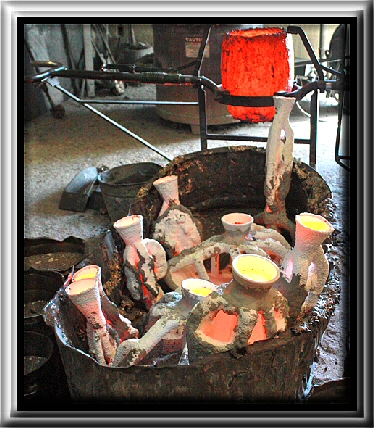

THIS IS A TWO (2) PART MISSION, (FIRST PART) THE PLAQUES ARE MADE OF CAST BRONZE, ALSO KNOWN AS,"THE ENTERNAL METAL". LOST WAX BRONZE CASTINGS DATE BACK 6,000 YEARS AGO, TELLING A VISUAL HISTORY OF PAST CULTURES. THE USAF COMMEMORATIVE PROJECT LEAVES A LEGACY OF OUR BRETHERN FOR CENTURIES TO COME. THE BRONZE PLAQUES ARE TO BE IN PUBLIC PLACES THAT HAVE HEAVY FOOT TRAFFIC I.E. (RIVER WALK, SAN ANTONIO) OR FOR YOU TO PLACE YOUR BRONZE PLAQUE WHERE YOU FEEL IT BEST BELONGS. THE OBJECTIVE IS FOR THE PUBLIC TO SEE FOR CENTURIES THE SERVICES AND SACRIFICES OF OUR AIRMEN.

|

|

|

|

|

Bronze Plaque Honoring USAF Heroes |

Bronze Plaque Honoring A Fellow Brother In Arms |

|

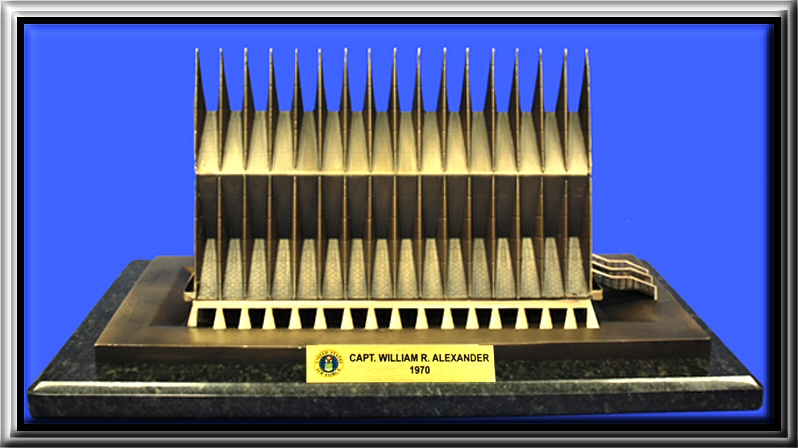

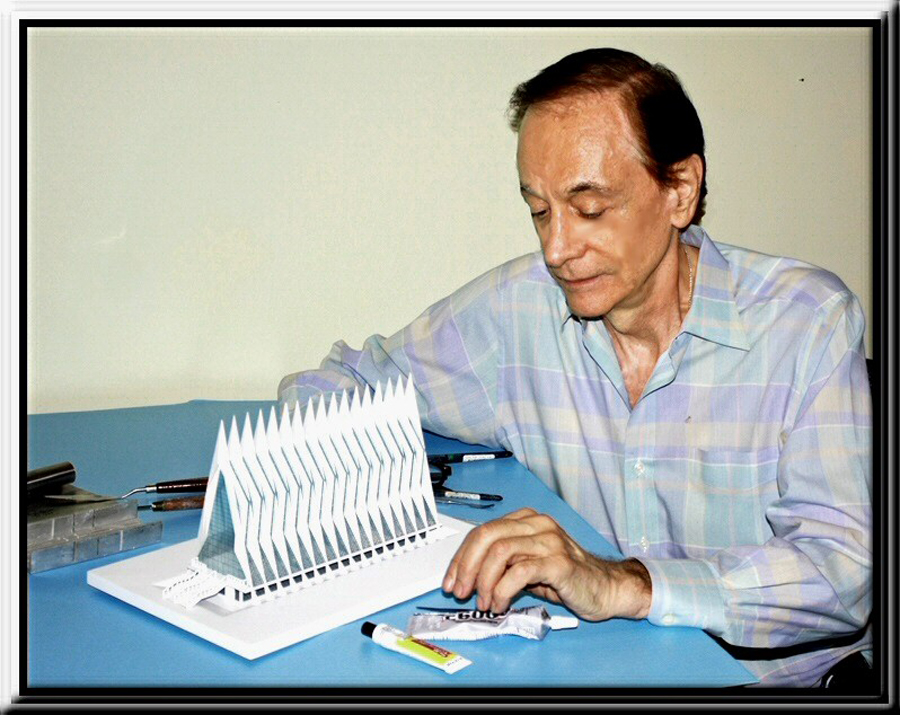

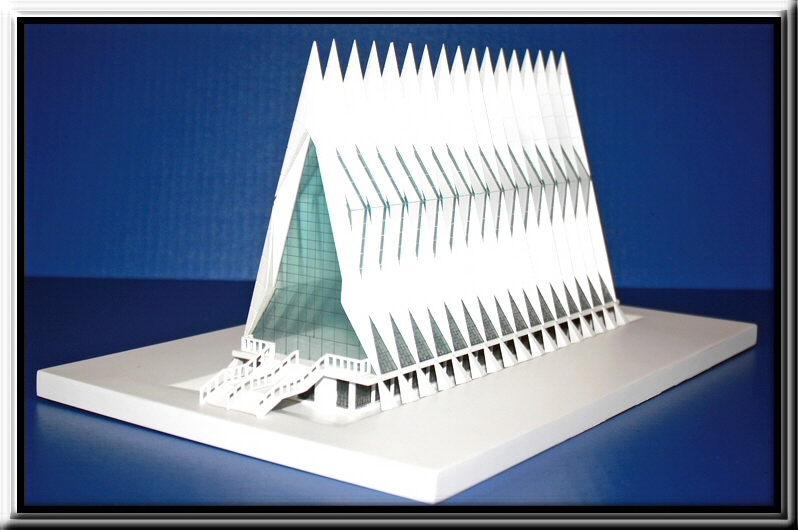

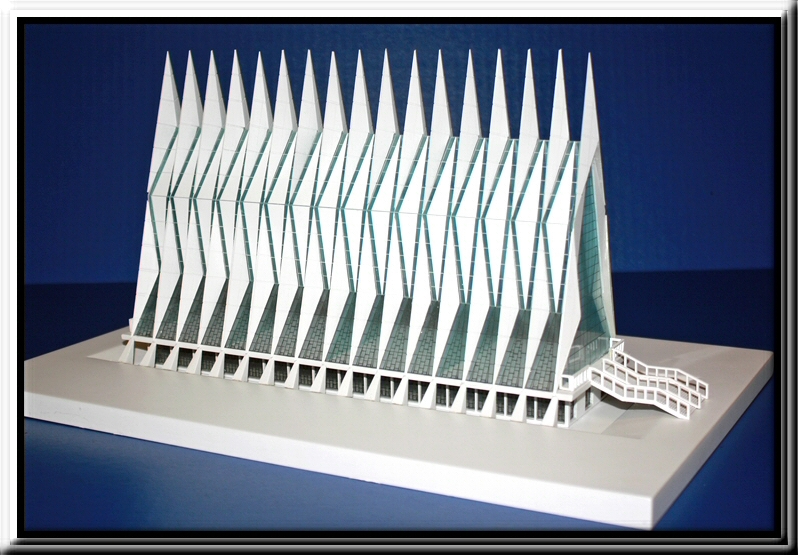

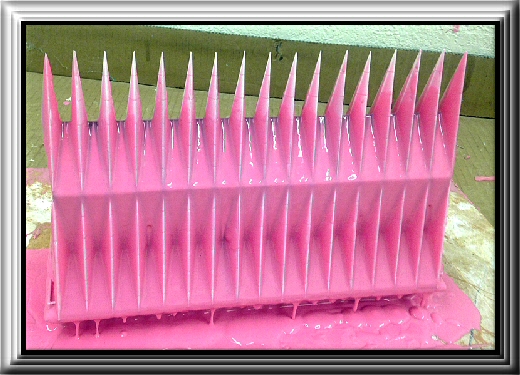

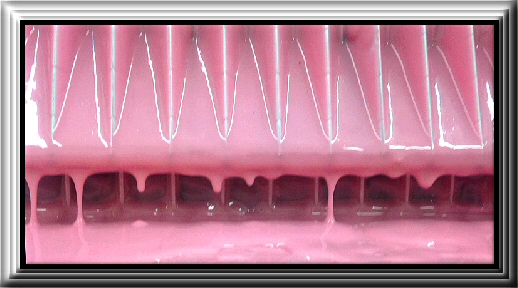

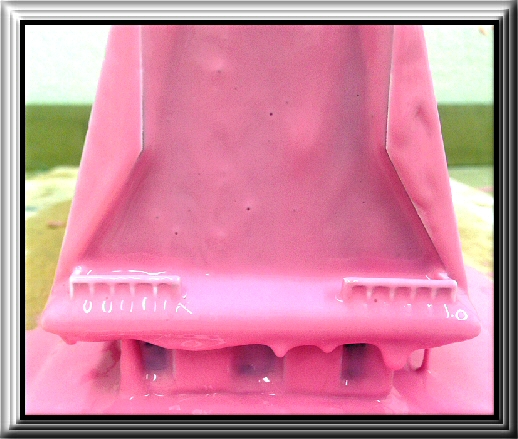

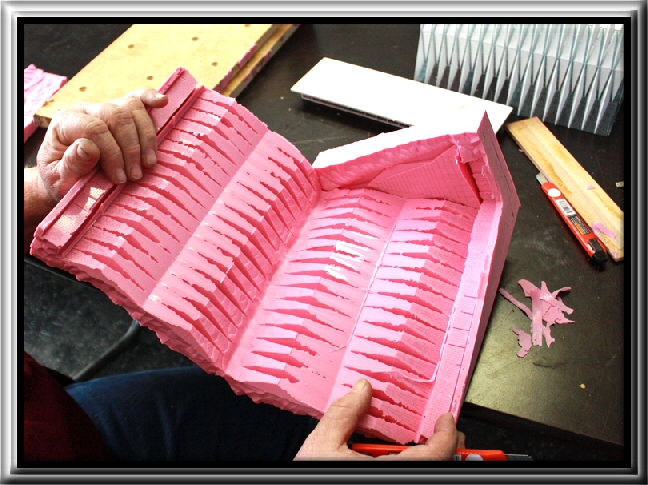

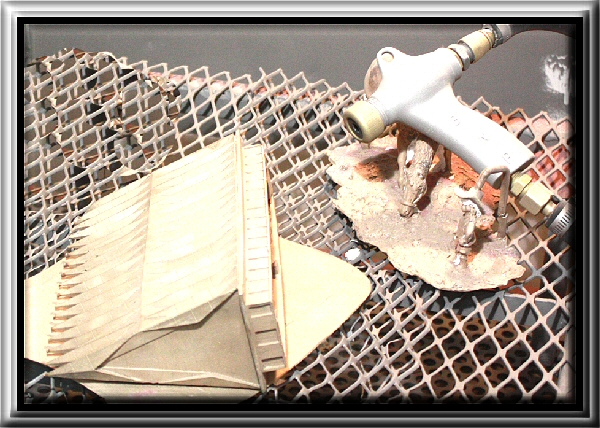

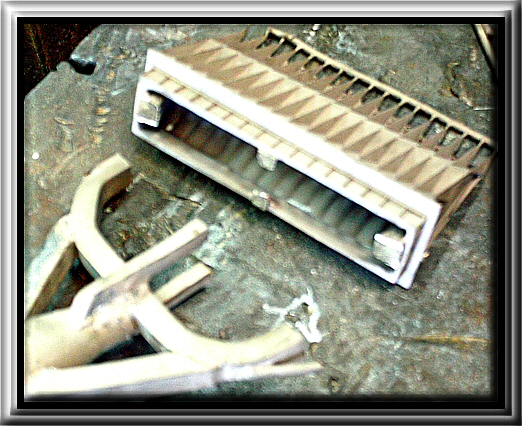

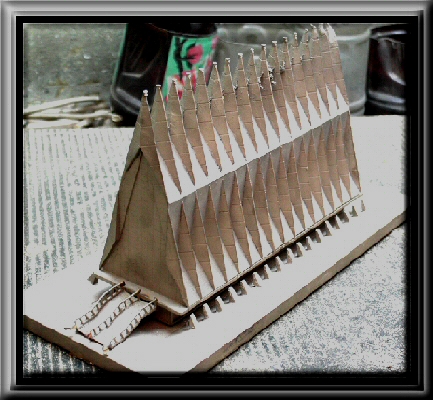

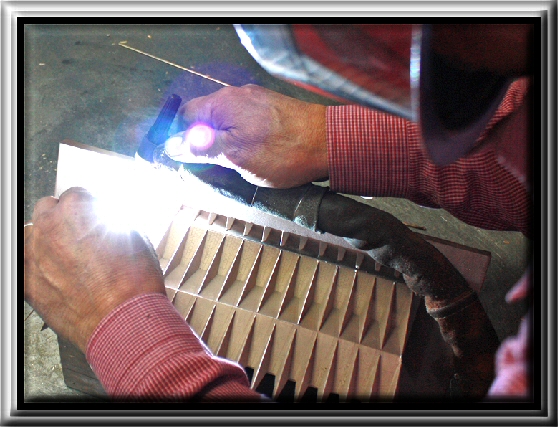

SECOND PART; A Memorial Treasure representing one of the most significant periods of a Cadets' life, never to be forgotten. |

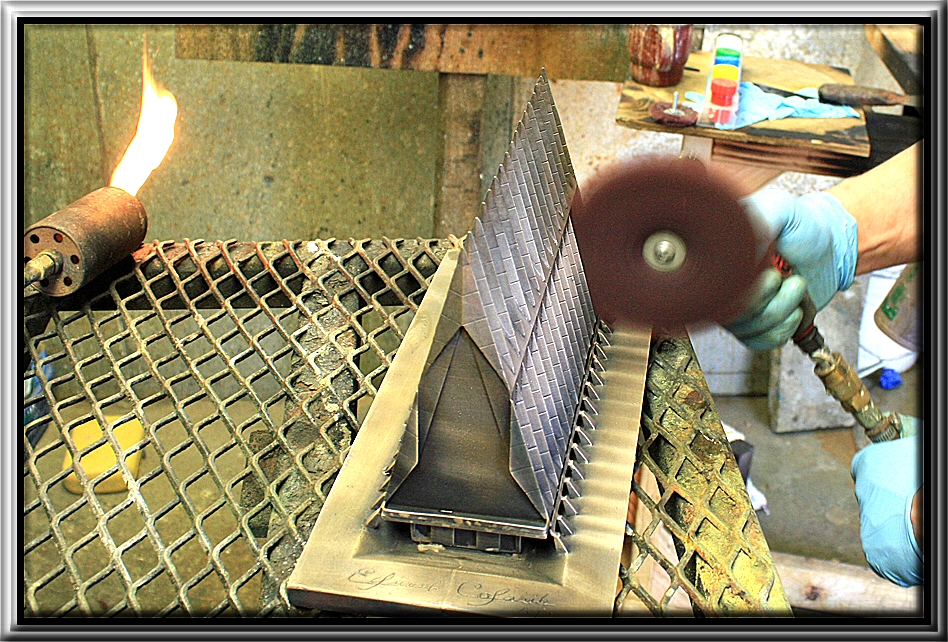

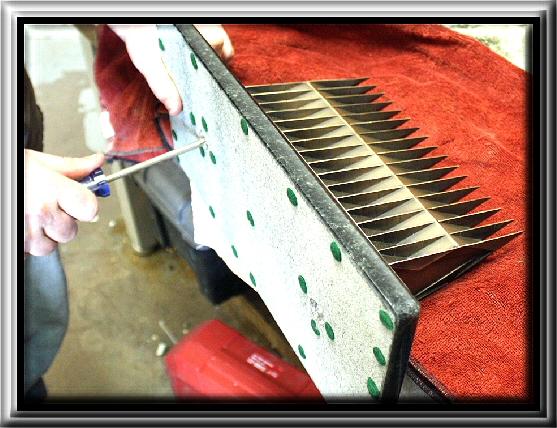

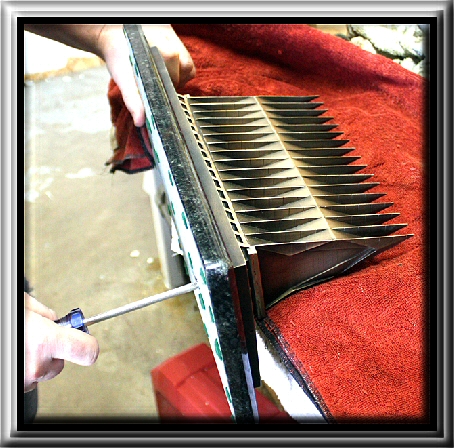

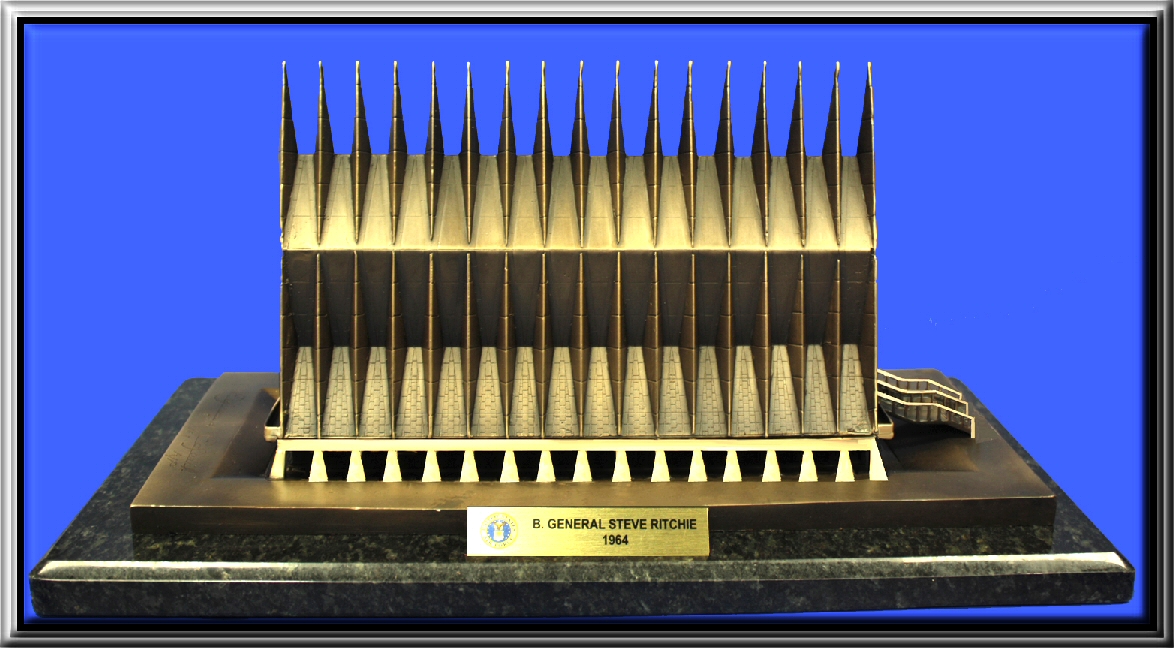

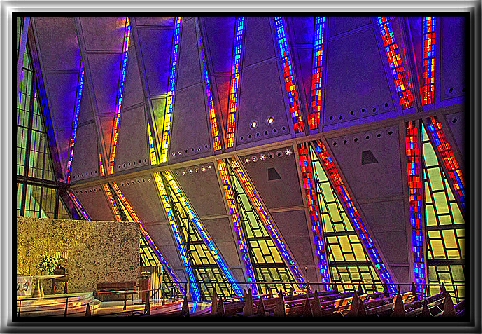

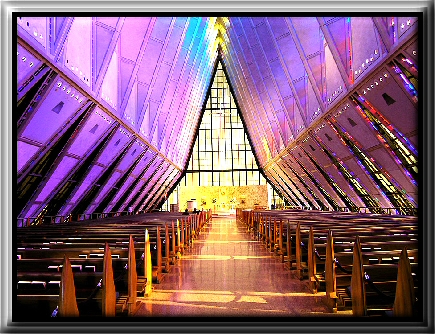

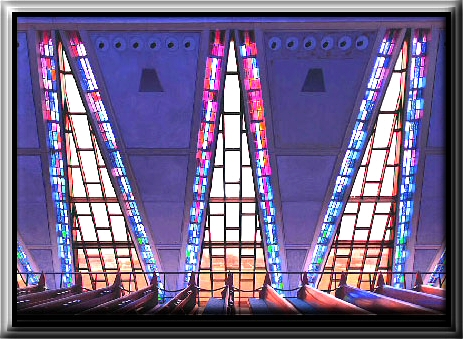

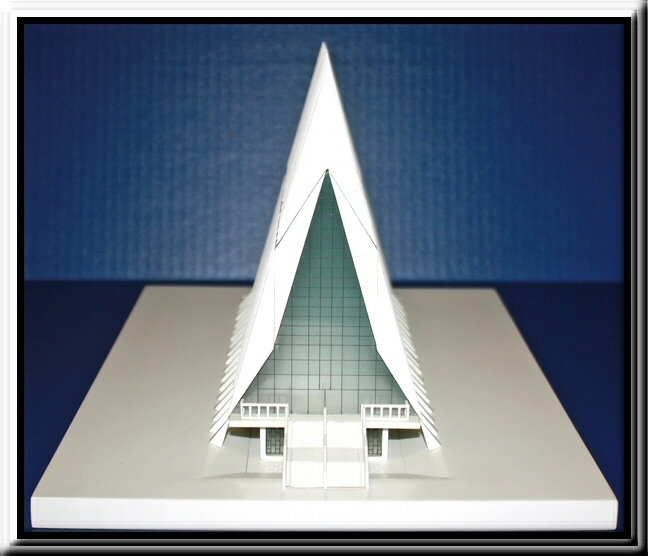

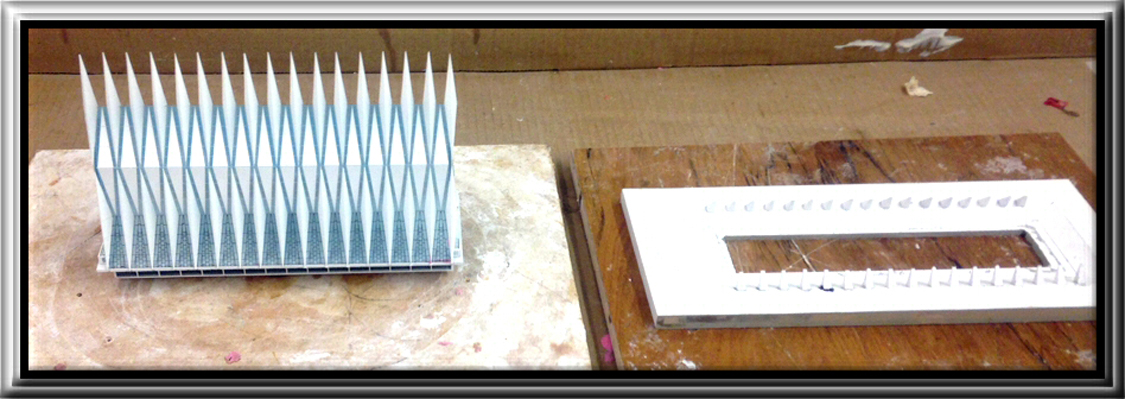

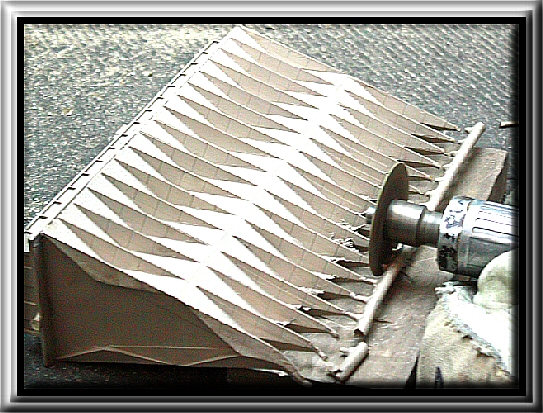

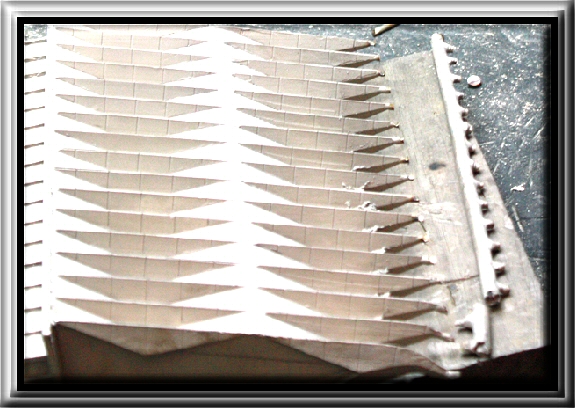

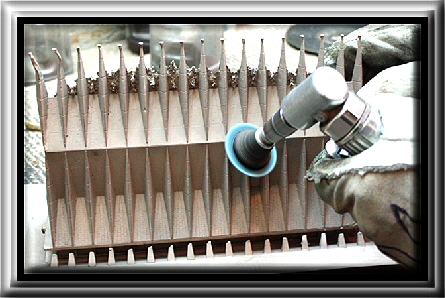

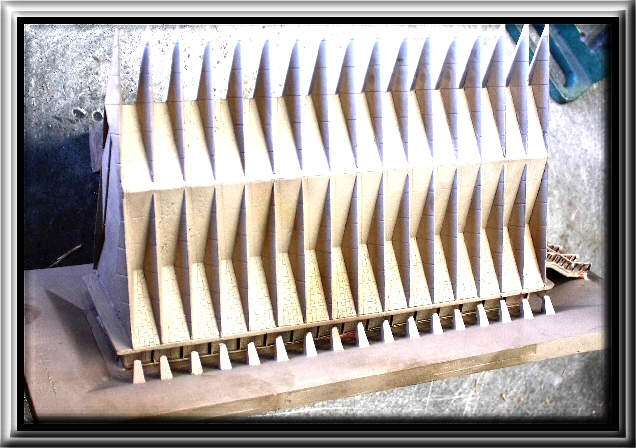

AIR FORCE ACADEMY CADET CHAPEL

Limited Edition Bronze Sculpture

Created by Edward Colarik, Master Sculptor.

Only 265 of these bronze art pieces will ever be created.

An Edition of 250 Numbered & Signed Bronzes; Special Edition of 10 Bronzes With Stained Glass Windows & 5 Artist Proofs.

Your Name And The Year You Graduated From The Air Force Academy Shall Be Engraved On a Placard.

Endorsed by Brig.General Steve Ritchie, USAF, Ret.

|

|

|

|

|

Air Force Academy Cadet Chapel Limited Edition Bronze Sculpture |

|

|

|

|

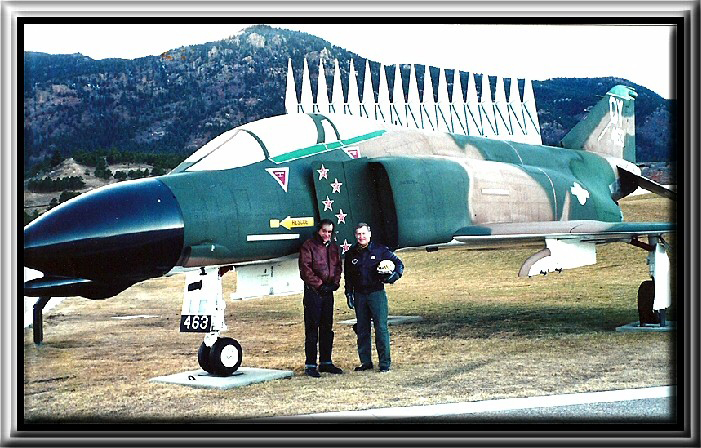

Brig. General Steve Ritchie with the Sculptor, Edward Colarik, of the AFACC Bronze Sculpture. |

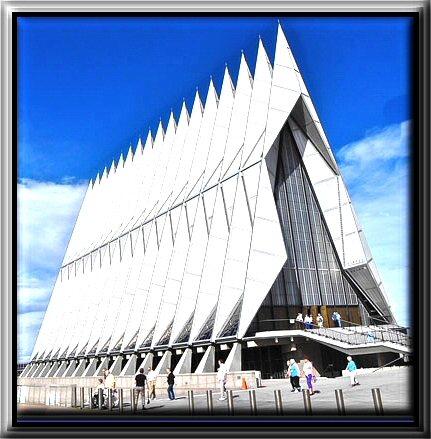

Air Force Academy Cadet Chapel |

|

|

|

|

|

Air Force Academy Cadet Chapel is an extraordinary architectial U.S. National Historic Landmark. |

.jpg)